SDGs Interviews: Talking Clean Water and Sanitation with Koji Kihara

SARAYA is one of Japan’s leading companies that implement the United Nations Sustainable Development Goals (SDGs). This is the sixth chapter of SARAYA’s SDG interview series telling the story of those behind SARAYA and how they are working to achieve these goals. In this edition, we spotlight Dr. Koji Kihara, General Manager at the Global Operations Division Sales & Marketing Dept. and former Director of SARAYA Biochemical Laboratory, talking about making Alsoft, SARAYA’s signature hand sanitizer and SDG number 6: Clean Water and Sanitation.

|

|

Born in the city of Osaka in 1951 when Japan was still recovering from World War II, young Koji Kihara used to do his own science experiments with kits provided with the children’s science magazine, dreaming of becoming a scientist one day. This is the story of Dr. Kihara, who created Alsoft, SARAYA’s most iconic hand sanitizer that is gentle on the skin and currently experiencing a surge in demand as the world fights against the COVID-19.

Could you tell us how you joined SARAYA?

SARAYA was a small hand soap company not too far from where my parents lived. As they were nearby, I thought visiting them was a good idea, since I was about to finish my master’s degree in industrial chemistry at the Nagoya Institute of Technology, a national university, and was looking for a researcher job at a company with an R&D facility.

After meeting the HR department, I was introduced to Mr. Shota Saraya, the founder and former president of the company, who passionately talked about SARAYA and its business. By the next day, the head of their Nagoya office came to see me at university and told me the president liked me and wanted me to join. Since I wanted a research job and the president was quite interesting, I joined SARAYA’s research team with only 2 other members in 1977.

I didn’t know what laid ahead of me, but I can say without a doubt that I have no regrets that I joined SARAYA. I was and I am quite proud to be a part of the company to which I could contribute creating innovative products like Alsoft (named Hibiscohol in Japan), a hand sanitizer that is gentle on skin, and other products like environment-friendly soaps and detergents. We now sell hand sanitizer to prevent infectious diseases in many parts of the world. Also, I obtained my Ph.D. in chemistry with my research while working at SARAYA, so I am forever grateful to my bosses like Dr. Taro Furuta, Dr. Kunio Shimamura, and many others who guided me to achieve my goals.

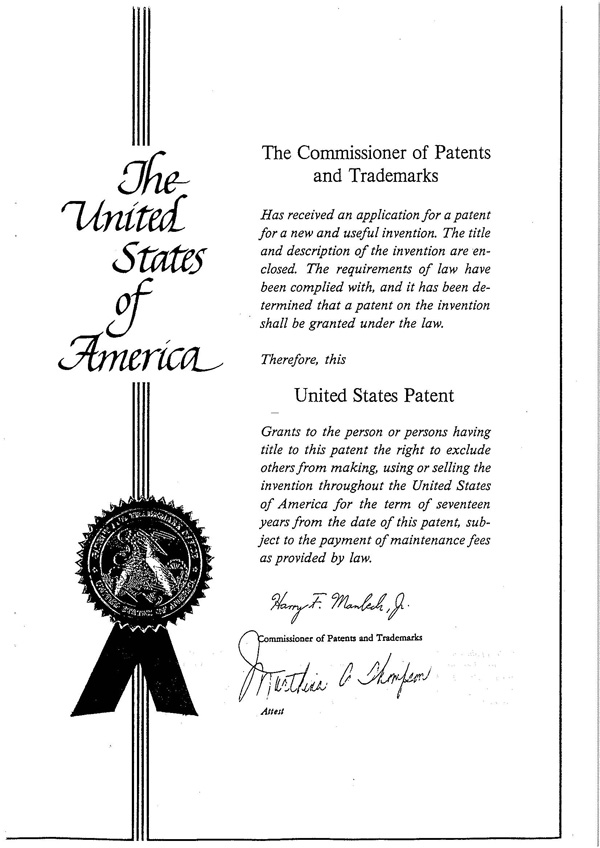

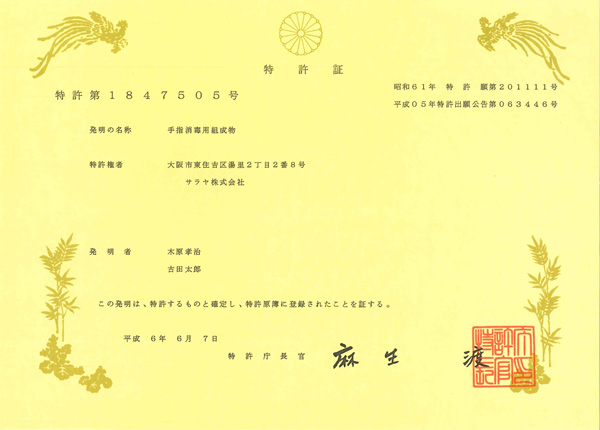

When we developed Alsoft, everything was new and we had to do it from scratch, but we had the working spirit to do it right. We sought solutions in many ways and we even filed patents for Alsoft hand sanitizer in Japan and the USA. That was also something new for us. Dr. Shimomura, the general manager of our Osaka factory made sure that we wrote good reports, correcting my report so much that my papers often turned red with comments and corrections. He kept “raising” hurdles for us, but to make us better. Thanks to him, not only was I able to get to where I am today, but SARAYA’s performance levels of research and product quality were improved to standards that I am still proud to share today with you.

When we developed Alsoft, everything was new and we had to do it from scratch, but we had the working spirit to do it right. We sought solutions in many ways and we even filed patents for Alsoft hand sanitizer in Japan and the USA. That was also something new for us. Dr. Shimomura, the general manager of our Osaka factory made sure that we wrote good reports, correcting my report so much that my papers often turned red with comments and corrections. He kept “raising” hurdles for us, but to make us better. Thanks to him, not only was I able to get to where I am today, but SARAYA’s performance levels of research and product quality were improved to standards that I am still proud to share today with you.

SARAYA promotes its employees’ growth. There are many who obtained their masters or Ph.D. after joining the company, like me. I submitted 10 theses based on the studies we completed, with half of them as the first author, to obtain my Ph.D. SARAYA has been a company with a great trajectory and vision.

Could you tell us about your background?

I was born to an average Japanese family of four (with an older sister) in Higashisumiyoshi Ward in Osaka, a residential part of the city. I was a curious boy who liked to create things, liking to check on many things like machines to know what’s inside and making things by myself, like when I needed a chair and I would just make it out of pieces of wood. Japan was rebuilding after World War II destruction and we didn't have many things available like nowadays.

I also used to do my own science experiments at home, with a subscription to a science magazine called “Kagaku” (science in Japanese) that included experiment kits. Sometimes the kit was an electricity experiment kit, another month it was a chemical experiment kit. I was anxious to experiment with them every month. Other than that, I used to run around outside with friends until it got dark. Maybe because of those science experiments I did in those days, I became a chemical researcher.

After graduating from high school in Osaka, I went to study synthetic chemistry at the Nagoya Institute of Technology (Nitech), a national university. After obtaining my bachelor’s degree, I worked for a textile dyeing company in Nagoya for one year, but the work wasn’t a research job, so I decided to go back to Nitech to major in industrial chemistry to study biomembranes, mechanism of membrane structure and how surfactant works on membranes for my master’s degree. There, I deepened my knowledge about surfactants, which I happened to work with later at SARAYA.

How was it to work at SARAYA laboratory, creating innovative products like Alsoft hand sanitizer?

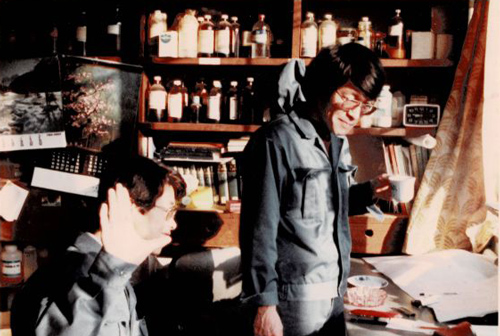

When I joined SARAYA in 1977, there were only two other researchers, which not much later got reduced to one, Dr. Furuta, whom we now call ‘Dr. Handwashing’ as he is the hand soap development specialist of SARAYA. The original laboratory we had was a very small room in a not-so-pretty, prefabricated building without an air conditioner. Nonetheless, a lot of great things happened there.

|

| Companions taking a break at the lab. |

We were young and everything was new. As SARAYA is a company of hygiene, I started to do bacterial tests. They gave us themes and we did countless experiments every day. Although the lab was small, the way we conducted experiments was quite proper and we were obliged to make detailed reports about the results. That’s how I learned to write good reports. Moreover, we had to write academic papers to submit to international academic journals periodically, writing them in Japanese as well as in English. Imagine how many red corrections comments our papers there were! I learned so much after joining SARAYA. We struggled, but gradually our materials came to be selected and published in international academic journals.

As SARAYA initially made kitchen detergents for industry use, we continuously researched to make them better, with feedback collected by salespeople when making rounds visiting customers. I also accompanied the sales team, explaining things to customers and asking them directly about their needs. We conducted countless comparison experiments with competitor’s products in cleaning power, foaming and cost, etc. It was a fun process to see our products getting improved nonstop.

|

| A young Kihara in the laboratory. Photo taken from Mr. Shota Saraya's autobiography. |

We didn’t always stay at the lab. When we came up with new products, we did presentations. We did it not only to our company executives but also to clients with our sales representatives. I remember when we went to one of the major fast-food chains for a presentation with our detergents, that got complimented for excellent paperwork. The way we wrote papers at SARAYA was just like at the university laboratory and it was our usual procedure that Dr. Shimomura, the head of the factory, thoroughly corrected them like a university professor. They were so well-organized that the major fast-food chain, whom we won a deal with at that time, said they had never before seen such good papers. And, with those papers, I was able to earn my Ph.D. degree later.

I think the spirit of SARAYA always helped us. We had themes to study, but how we do was up to us. A family-like, free atmosphere helped us to excel.

How did you come up with Alsoft, SARAYA's groundbreaking hand sanitizer?

SARAYA came up with their first hand sanitizer in 1977, the year I joined. It was alcohol-based and contained chlorhexidine as a disinfectant. In theory, these ingredients are disinfectant and kill germs, but when you put it on your hands, alcohol can cause skin damage. To prevent that, we would mix emollient, a substance that moisturizes skin, but quite often emollients reduce the disinfecting power of sanitizer. So we began to research to find the right emollient which did not reduce that power.

We have studied our competitors’ products, checked on ingredients and experimented with many different solutions to look for the right emollient, conducting experiments to check on the effectiveness of bacterias like Escherichia coli and Staphylococcus aureus. The lab was boiling hot during summertime without an air-conditioner, but we had to shut all the windows and doors so that dust didn't fall on the Petri dishes we used to culture our samples. We had towels around our forehead so that our sweat did not drop on samples while cold wet towels rested on our shoulders to cool us down. In those days, we didn't even have micropipettes in our lab! Instead, we used regular pipettes to suck up the bacterial fluid, so sometimes the fluid got into our mouths and we would spit it out right away. I now fondly recall those incidents.

Our 5th researcher was a woman and the company finally installed an air conditioner. What a relief we had! We have researched many possible emollients for quite some time and finally, we found one. This emollient did not reduce the disinfecting power in hand sanitizer, but surprisingly it actually enhanced it. It was so exciting!!!

After a number of tests to confirm the effectiveness, we started filing patents. That was the first case at the company and no one knew how to do it, but we somehow managed with the help of a patent attorney in Osaka, getting it in Japan as well as in the USA. We named the product Alsoft (Hibiscohol in Japan). It hit the market in 1990 and it became not only a long seller but also widely available in many countries now. Especially with the pandemic. It is an important product to fight against infectious diseases like Covid-19.

|

|

What was the most memorable project with SARAYA regarding SDG6, Clean Water and Sanitation?

It’s definitely the Alsoft project, which took a lot of effort, creating it from scratch. We created a solution to fight against infectious diseases and what I like most is that it is still widely used. We are now expanding our business into many other countries to help their hygiene.

I can still vividly remember when the product came out. I think one of the reasons for the achievements was that we were involved with every process of development. Since I put so much effort and time into it, the product became like my child.

Although Alsoft permits sanitation without the use of water, even if we focus only on the “Clean Water” part of this SDG, SARAYA also has products that help to protect it. For example, I was one of the main researchers to create a hand soap without white turbidity agents (agents that add cloudiness to soaps, giving them their pearly white, liquid look) in 1999. These agents normally derive from petrol, so eliminating them from our products made them more biodegradable, protecting the purity of water after washing your hands. We no longer have this kind of product as we have shifted to foam type soaps, but “protecting water” and “biodegradable” were and will always be key concepts we follow at SARAYA, showcased in current products like Happy Elephant and the use of SOFORO, our natural cleaning agent.

I once wanted to go to work in a big corporation, but I wonder if I did it, I would have just become a cog in a wheel. SARAYA appreciated my achievements and I later became a director and head of our biochemical laboratory.

|

| Launch of the SARAYA Goodmaid plant in Malaysia. Dr. Kihara second from left. |

What are the future plans of SARAYA regarding SDG 6 Clean Water and Sanitation?

We plan to take products like Alsoft and the concept of hand hygiene to many different parts of the world. Currently, I am involved in projects with our factory in Malaysia, helping them maintain the quality of products. We want to spread our great products, backed by evidence and a sense of sustainability, not only in Asia but also around the world so that more people can enjoy sanitation while protecting the environment, which is part of Saraya's mission. We want everyone to be able to live safely and happily.

|

| Mr. Kihara teaching employees in Malaysia. |

Please give a message to the next generation

The reason why SARAYA is where it is today is because of its solid manufacturing practices. Maintaining a constant, high level of product leads to trust. Research evidence is important to maintain quality, something that all SARAYA’s products share as they are based on evidence and high quality. I hope this tradition will continue.

My message to the next generation is that you need to keep studying with curiosity and enthusiasm. And go abroad to broaden your horizons.

When I look back on my life, I really enjoyed my trajectory with SARAYA. I love every part of it. Of course, there were times when things were tough. But if you don't give up and keep working hard, you will find moments filled with joy.